Technical specification of basic material

NedZink produces titanium zinc in accordance with EN 988 & ASTM B69, an alloy based on electrolytically refined zinc with a purity of min. 99.995% Zn (Z1 in accordance with EN 1179) with small additions of the alloy elements copper, titanium and aluminum.

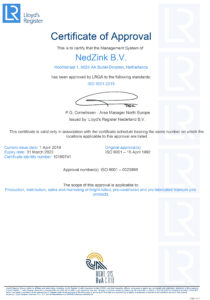

The chemical composition, the mechanical and physical properties and measurement tolerances are determined in the KOMO product certificate and the product certificate from Lloyd’s Register, Industrial Quality Scheme for Product Certification by Surveillance of Quality Systems (approval No. QIS 122).

Compliance with the established material properties is checked at regular intervals (several times a year) by an independent and neutral inspection body, Lloyd’s Register.

The materials are provided with a continuous stamp featuring a mark in accordance with the provisions of NEN-EN 988, mentioning the producer, the product description in German, Dutch, English and French, the EN 988 & ASTM B69 standard, the nominal thickness, the batch number, the year of production and the logos of the Lloyd’s Register and KOMO inspection bodies.

The product certificate and the ISO 9001 certificate for the quality management system at NedZink ensure consistent and uniform high quality.

NedZink titanium zinc is characterized by high durability and excellent deformation properties, and is extremely weather-resistant, durable and maintenance-free.