Soldering

Soldering is the process of connecting two metal parts using another metal that has a lower melting point. The metals to be connected are not melted in the process. The metal that creates the connection is the solder.

The soldering work must be carried out in such a way that the solder fl ows satisfactorily, and the minimum overlap requirements are satisfied:

– For vertical soldered joints (e.g. rainwater downpipes) and soldered joints of gutter ends and other accessories min. 4 to 5 mm.

– For horizontal and inclined soldered joints an overlap of min. 10 mm.

These are strength joints.

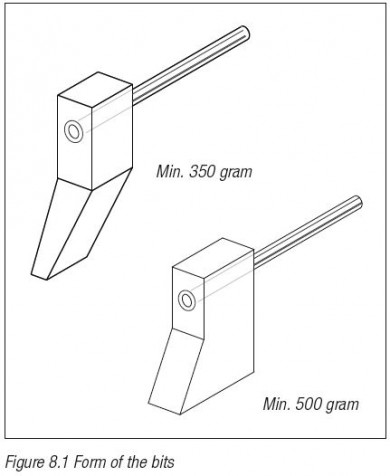

One must use a soldering bit with a weight of more than 500 gram, which must be used at the correct temperature (350-400 °C).

A bit with a fl at sole and a width of 10 – 15 mm gives the best results for soldering most joints in zinc work. One may need a bit with a different form, min. weight 350 gram and a sole of 5 mm in width, only for places that are diffi cult to reach. For the form of the bits see Figure 8.1.

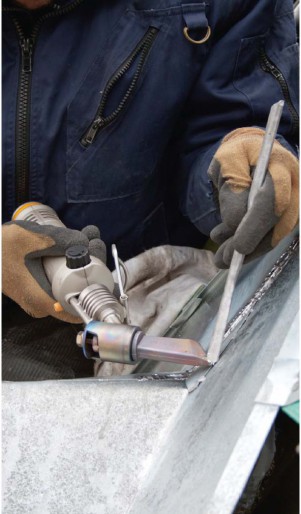

The lifespan of a soldering bit is determined by regular maintenance. The copper oxide on the bit will always have to be removed and deeply worn bits must be forged into the proper shape. Copper oxides and fl uid remnants on the sole of the bit are removed using a sal ammoniac block. This is achieved by rubbing the soldering bit back and forth on the stone at working temperature.